The Palecek line of furnishings and décor are so well-suited to the relaxed style and eco-conscious mindset of California. I recently had the opportunity to go behind the scenes and attend a tour of the Palecek Factory, hosted by Luxe Magazine and Palecek.

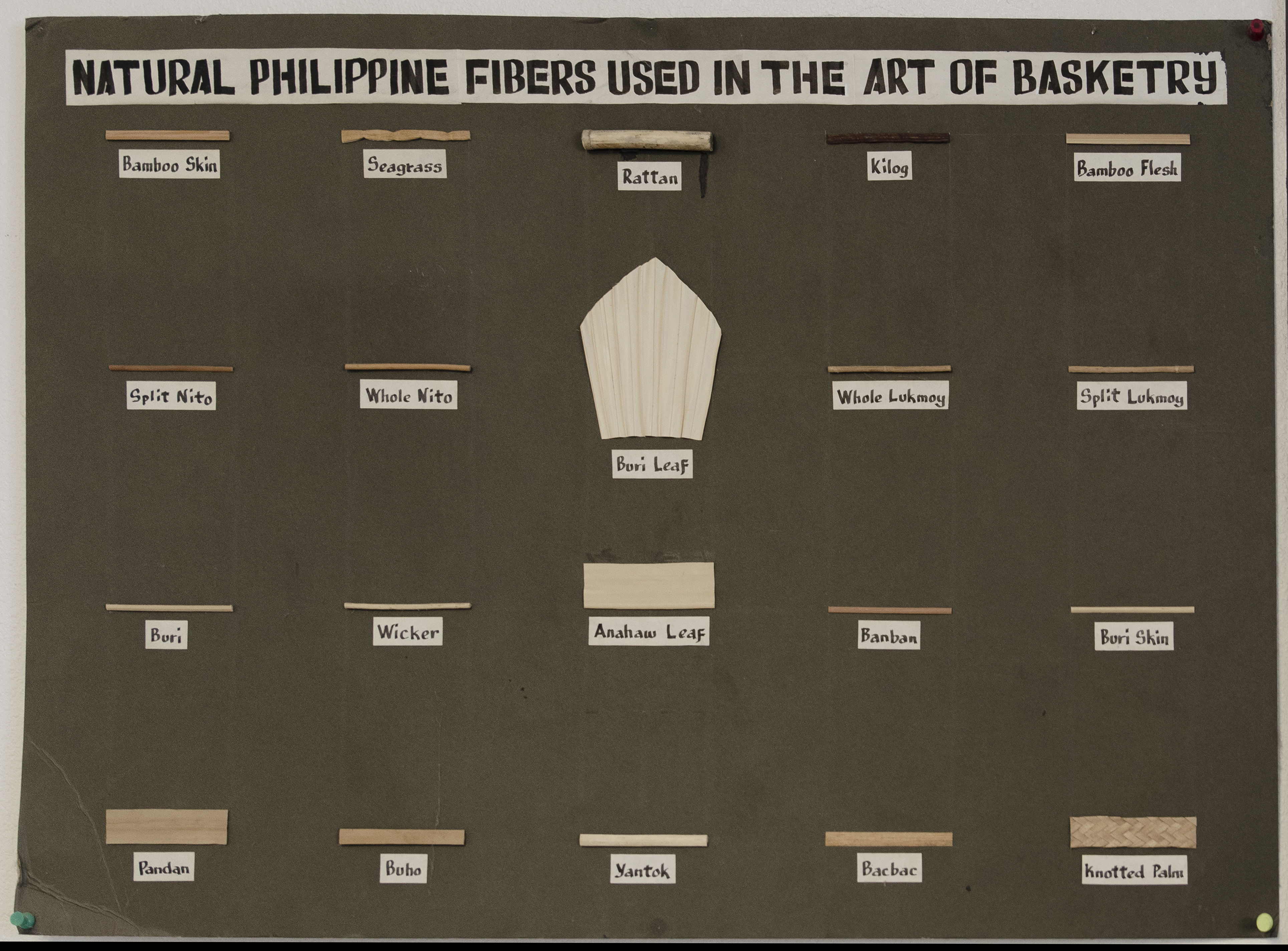

For over 40 years, Palecek has been creating furniture that focuses on the use of natural fibers derived from renewable resources. They have beautifully merged high design with sustainability, creating products that elevate any design, and will last for years to come, both in terms of style and durability.

It was fascinating to learn more about how the products are manufactured and crafted to stand up to the test of time. The tour began in the Quality Control Department, where we learned about tests for strength and durability.

We also got to watch as one of the technicians skillfully used a torch to burn off any minuscule debris that would interfere with a smooth finishing process. Don’t you sort of want this job?

Next, we headed over to the Paint and Finishing Department where we learned about the different fibers and how they accept finishes. Palecek has been developing their finishing techniques for 40 years, and some of their processes involve over 10 steps to get the right depth and variation of color along with the desired durability.

The term ‘COM’ stands for Customer’s Own Material. This is when the interior designer selects a non-standard fabric for a piece of furniture. The fabric will come from a different vendor and has to get matched up with the correct piece of furniture, and applied in just the right way. As you can imagine, there are about a thousand points at which something could go wrong! This is why it is essential that designers and their trade partners have systems and expertise to ensure that the results match the high expectations of custom design.

The head of the COM Department at Palecek shared with us her methods to ensure that our fabrics get matched with the correct furnishings, and that each piece turns out beautifully.

Additional stops on the tour included Cutting and Sewing, as well as the Upholstery Workroom, where we got to observe a skilled team of seamstresses and upholsterers at work, carefully planning the placement of patterns, seams, nailheads, and all of the finishing touches.

After touring much of the 200,000 square-foot factory, we had worked up a serious appetite, and our hosts did not disappoint. We sat down for a lovely lunch, and I got a jump start on sourcing from the new catalogue!

A huge thank you to the teams at Palecek and Luxe Magazine for organizing this inspiring and educational event!

share it

email it